Production Machining

At Mauston Tool Corporation, our production machining capabilities are built around one core promise: delivering precise, repeatable, and reliable parts every single time. Our team of highly skilled machinists combines decades of hands-on experience with advanced CNC technology to produce complex components to exact customer specifications. Whether it’s high-volume orders or tightly controlled short-run batches, we maintain the same level of accuracy, efficiency, and attention to detail that has defined our reputation in the manufacturing industry.

Machining Capabilities

- Okuma Multus B250 II ISW/750

- Okuma MB-4000 4-axis

- Okuma MV560-V

- Okuma MV660-V

- Makino S56

- OKK VM 7 III

Measurement Capabilities

- CMM Zeiss Contura 6206

- Tesa-Hit Magna magna Micro Hite

- Qty (2) Mitutoyo microscopes

- Mitutoyo Profile Projector with 1/10 readouts

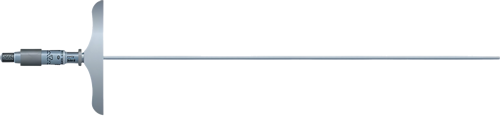

- Handheld guages includeing: Micrometers, dial indicators, depth micrometers, thread guages, and digital indicators

- Rockwell hardness testers

Production Machining Facility

Guaranteed High Quality Components every time. Mauston Tool Corporation maintains efficient workflows, optimized setups, and repeatable machining processes that minimize downtime and maximize accuracy. TBy pairing advanced machinery with proven job management systems, we deliver dependable turnaround times, stable part quality, and cost-effective solutions for both emerging product lines and long-term manufacturing programs.

Mauston Tool is your trusted source for mold building and production machining since 1978. We provide the highest level of quality and customer satisfaction. Our employees are highly innovative and dedicated craftsman who strive to not only meet, but exceed your expectations.